Sheep systems for maximising profit from perennials at Hamilton EverGraze Proof Site

Achieving greater profits from perennial pastures balances profitability against increasing profit variation and environmental risks from the utilisation of pasture and use of resources. Profitability of livestock enterprises is primarily addressed by increasing pasture production, pasture utilisation (primarily through stocking rate), livestock performance and limiting the amount of supplementary feeding. The aim is to produce greater wool and meat per hectare without increasing financial and production risk due to climate variation or risk to the environment.

Main findings

Stocking rates lifted based on pasture production

- Hamilton EverGraze pasture systems allowed stocking rate to be 25-31 DSE/ha from 2006-2010 compared to 16 DSE/ha for the average benchmarked Livestock Farm Monitor Project farm over the same period.

Increased reproductive rate for increased production per hectare

- Comparisons between sheep systems raising twins compared to singles showed increased lamb liveweight per hectare and higher gross margins per hectare for systems with higher reproductive potential despite lower lamb weaning weights and survival of twins.

Higher variability in gross margins with increased stocking rates

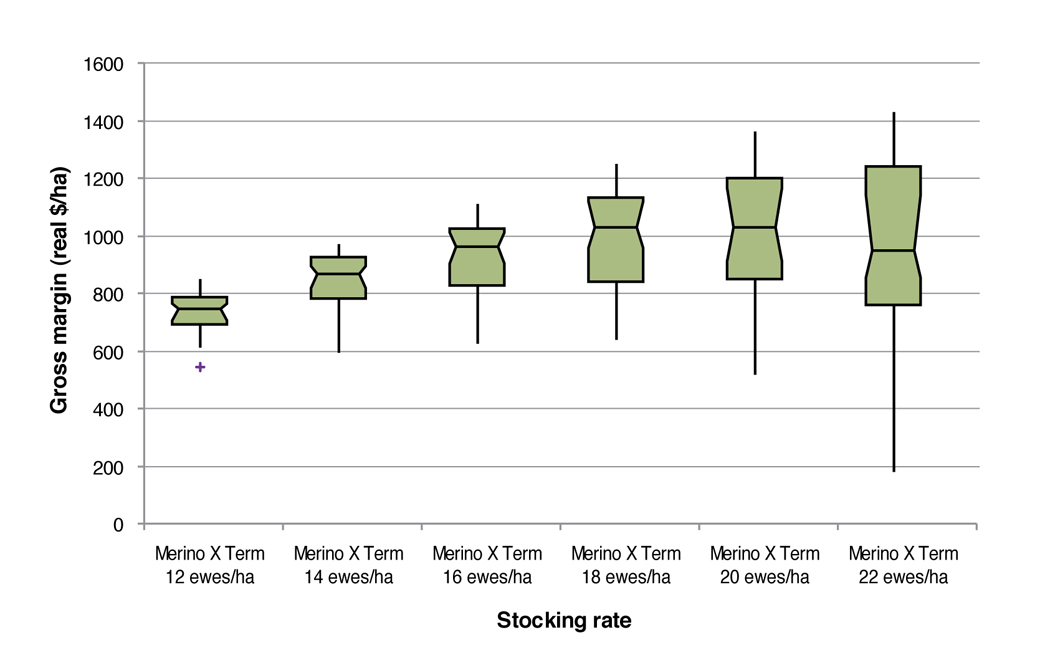

- Modelling indicated that while the gross margin per hectare increased with higher stocking rates, the variability of the gross margin became greater in excess of 18 Merino ewes/ha (34 DSE/ha, based on a 55kg ewe). The thresholds for feed on offer (< 800kg DM/ha by March) and supplementary feeding (>30 kg/ewe/year) were also exceeded more frequently up to 50% of the time at the highest stocking rate tested.

Optimum lambing time

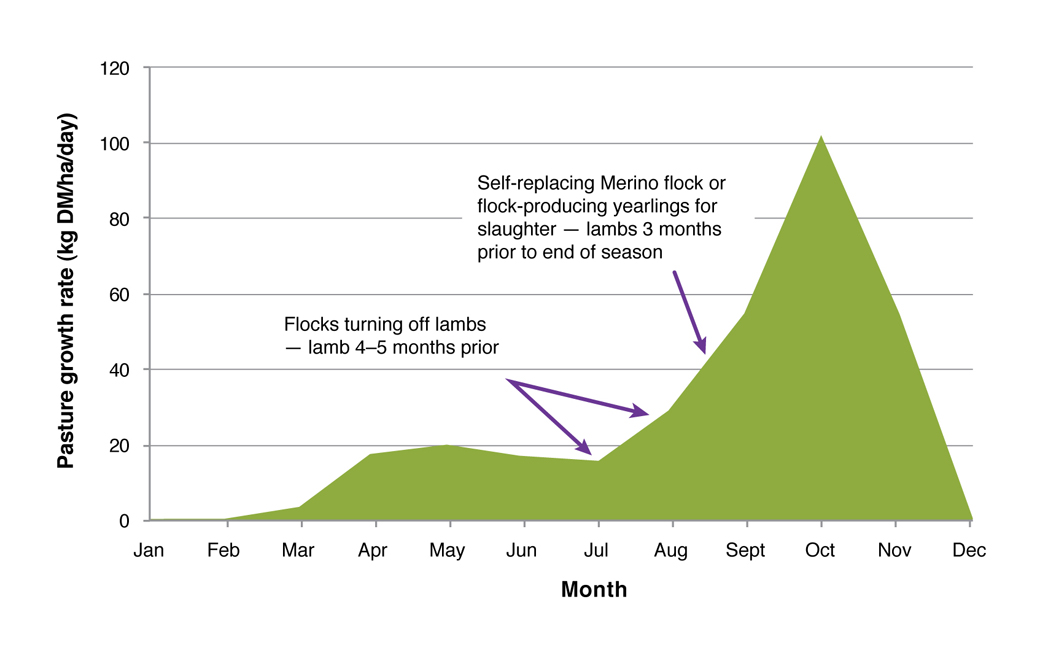

- September and August lambing times were able to produce high lamb liveweight per hectare from the pasture systems. This lambing time was selected to produce store lambs (35kg) at the site and was consistent with modelling work (Warn et al. 2006) which indicated that lambing time needed to be five months, four months and three months prior to the end of the growing season for production of finished lambs, store lambs and Merino weaners or Merino yearling lambs respectively.

Summer active pastures are important for meat focussed enterprises

- Modelling indicated that while increasing winter production was of significant value to all sheep systems, as it impacts most on stocking rate, summer active perennials (such as lucerne) were of most value to meat production systems and those with a later lambing time as they contributed to extra liveweight of lamb produced.

- Other modelling indicated that lambs could be finished to higher liveweights in January in 60% of years in the Triple pasture system (compared to perennial ryegrass) and this would result in higher gross margins per hectare in those wet summer years.

- Summer active pastures also allowed for maintenance of sheep on pasture and lower supplementary feeding in summer and autumn following summer rain in a drought year (see Lucerne reduces risk, provides options for livestock and prevents salinity).

Similar production from Merinos and Coopworths

- Modelling and benchmarking studies of prime lamb enterprises generally show that the most profitable system produces both meat and wool. However, gross margins from the Coopworth Composite and Merino x Terminal enterprises turning off store lambs at Hamilton were relatively similar in both years tested. The reason was that both systems performed well but differently in terms of reproduction and wool production. Average lamb weaning percentages when accounting for dry ewes were approximately 92% for Merino ewes and 141% for Coopworth ewes; while wool contributed up to 30% of the income in the Merino x Terminal system, compared to 4-7% in the Coopworth system.

- In both systems, following Lifetimewool guidelines, providing hedgerow shelter to a proportion of ewes and their lambs and using genotypes with increased reproduction resulted in weaning percentages that were higher than the average benchmarked Livestock Farm Monitor Project farm, which were 80% and 118% for Merino and prime lamb enterprises respectively.

For overall profit and production results of the Hamilton Proof Site pasture systems, along with details of the pastures results, see the Hamilton research message Right Plant, Right Place, Right Purpose, Right Management.

Read more about this research

Background

The South West region of Victoria has reliable rainfall with good soils that support high levels of animal production, but the question is whether gross margins can continue to increase to keep up with rising capital value and input costs.

To ensure profit margins are maintained, productivity needs to increase by either; spreading cost over more product (utilising the resource more efficiently) or increasing inputs to produce marginally more outputs.

Achieving profits from perennial pastures is at the most basic level about resource use efficiency. Pasture grown is usually the cheapest source of energy and protein and the most profitable way to turn this into livestock product is to improve utilisation, optimising the amount of clean wool or lamb product per hectare, while minimising feed costs.

Factors affecting how far utilisation (stocking rates) can be increased include; growing season, time of lambing (balance between peak pasture supply and peak animal demand), grazing management and attitude towards production and environmental risk.

Enterprise Selection

Enterprise selection is critical to profitability and modelling studies (Young et al 2004, Young et al 2010) have shown significant improvements in profit by selecting the most profitable enterprise and optimising the production system. However, many benchmarking studies (including the SW Farm Monitor Project) have continually shown that profitability varies widely amongst enterprise types and that in any enterprise type the top 20% of producers can achieve similar levels of profitability. Therefore selecting an enterprise based on experience, skills, facilities, management expertise and interest is also important as “it is not what you do but how well you do it” and swapping to a different enterprise does not necessarily generate more profit.

Pasture utilisation and increasing stocking rate

Stocking rate is the biggest driver of pasture utilisation and profit however this needs to be considered in the context of growing season, lambing/ date, enterprise, and sustainable management. There is a trade-off between consuming as much as possible during the spring peak and ensuring the rest of the year isn’t spent feeding excessive amounts of supplementary feed to maintain livestock or overgrazing pastures in the summer/autumn impacting on feed on offer and ground cover thresholds.

Growing season and distribution of pasture growth

The potential stocking rate or carrying capacity for a region will be largely influenced by growing season length and it will also help govern the most appropriate time of lambing for different enterprises. Growing season length is estimated from the autumn break to when pastures dry off in late spring. A study conducted throughout south-eastern Australia (Saul and Kearney 2002) found that the variation in growing season length explained about 67% of the variation in stocking rate. The growing season of a perennial pasture will be influenced by rainfall, soil type, soil fertility and the predominant pastures species.

Time of lambing

Selecting an appropriate time of lambing by matching the increased feed requirements of lambing ewes to peak pasture growth, is the first step to optimise pasture utilisation. The most appropriate lambing time is a compromise between many different factors including the type of enterprise (eg: meat vs. wool, store vs. finished lamb), breeding season of ewes and rams, pasture growing season, the availability of other feed resources (eg: forage crops, stubbles) and possible conflicts with other farming activities. This also needs to be considered in the context of marketing objectives for the enterprise being run i.e. producing store lambs or finished lambs to specific liveweight or carcass weight.

Reproductive Rates & Weaning Percentages

Increasing reproductive rate and weaning percentages increases the number of lambs per ewe stocked and hence can be critical to the amount of product produced per hectare. Increasing weaning percentage requires increased attention to ewe management through the management of ewe condition score and ewe nutrition. Additional management strategies such as the provision of shelter will also be important for increasing survival and lamb turnoff.

Attitude towards risk

Running higher stocking rates and higher performing enterprises may present increased risks for producers and add complexity to the business. Consideration needs be given to the risk of excessive bare ground at the autumn break or higher supplementary feeding costs to maintain ewes at target condition score throughout the year. The highest sustainable stocking rate will consider time of lambing and growing season to help balance these risks. Additionally other risks such as animal health will become more important under high stocking rate production systems.

What was done

Pre-experimental modelling

Modelling was undertaken to determine the profitability of different enterprises and test the influence of a variety of factors (Young et al. 2004). This found that by adopting either the Best Practice Perennial Ryegrass or Triple pasture systems (described below) profit would increase from;

- $100/ha to $263/ha (Perennial Ryegrass) or $226/ha (Triple) for Merino wool enterprises;

- $172/ha to $409/ha (Perennial Ryegrass) or $397/ha (Triple) for Merino by terminal prime lamb enterprises;

- $34/ha to $305/ha (Perennial Ryegrass) or $290/ha (Triple) for 1st Cross ewe prime lamb producing enterprises.

A number of other associated factors such as weaning percentage, growth rate of pasture in various seasons and time of lambing were also modelled. These enterprises and factors were then tested across pasture systems designed to increase both profitability and reduce ground water recharge.

Pasture systems

The Hamilton EverGraze farming system experiment was established during spring 2004 and autumn 2005. Three perennial pasture systems were developed from the results of pre-experimental modelling and agronomic selection of pastures suited to well-drained crests, slopes and poorly drained clay flats at the Hamilton EverGraze site. Full details of the experiment can be found on the Hamilton Systems Experiment page. In summary, the pasture systems were:

- Perennial Ryegrass System; early flowering ryegrass (cv. Fitzroy) on the crest, mid flowering ryegrass (Avalon) on the slopes and late season ryegrass (cv. Banquet) on the valley floors.

- Triple System; where perennial ryegrass was replaced with semi winter active lucerne (cv. SARDI Seven), on the crests and summer active tall fescue (cv. Quantum) on the valley floors.

- Novel System; Chicory (cv. Grasslands Puna) was used on the crests, Italian (2006, 2007)/late finishing perennial ryegrass (cv. Banquet) (2008) ryegrass on the slopes and kikuyu (cv. Whittet) on the valley floors.

All pastures were sown or oversown with a mix of subterranean clovers (cv. Leura and Gosse) and white clover (cv. Mink).

Livestock systems

For the first two project years, CentrePlus and Toland Merino ewes were joined to terminal sires. The ewes were put on the pasture in February 2006 and lambed down separately as either single or twin bearing ewes in 2006 and 2007. The project used twin and single lambing Merino ewes (joined to terminal sires) as a proxy for higher and lower reproduction rates in a Merino x Terminal production system. This enterprise had been modelled pre-experimentally as being the most profitable and most responsive to increased weaning percentage (Table 1). Estimated gross margins were significantly greater from the twin lambing systems due to greater lamb production per hectare despite lower live weights at turnoff than single lambing systems.

Table 1. Increase in profit ($/ha of pasture) achieved from producing an extra 10% lambs weaned for four flock/enterprise types on current (traditional south west Victoria) pasture systems, and the Hamilton Proof Site high performance perennial ryegrass and the triple pasture systems (Young et al. 2004)

| Wool focused enterprise | Meat focused enterprise | |||

| Pasture System | Traditional wool | Wool/meat | Wool-meat terminal | 1st cross |

| Current |

8 |

17 |

26 |

23 |

| Perennial ryegrass |

14 |

28 |

40 |

30 |

| Triple |

13 |

30 |

44 |

27 |

In the final two years of the experiment, Merino and Coopworth ewes (joined to terminal sires) were stocked on the site from May 2008 and they lambed in September 2008 and August 2009 as flocks containing scanned single, twin and triplet bearing ewes. In this circumstance the treatment of a high reproductive rate livestock system (Coopworth/composite ewes producing prime lambs) was maintained and tested against the comparatively lower reproductive rate of the Merino x Terminal enterprise (Table 2).

A steer/heifer back-grounding system was also run, with the animals stocked in autumn 2006, 2007, 2008 and sold the following December or January. A cow-calf system grazed from January 2009, with Angus and Charolais-cross cows mated to Angus bulls for a September calving. The results of the cattle systems are currently being compiled and will be presented in a separate message.

Table 2 shows the treatment design and matrix applied across the experimental site at Hamilton. The carrying capacity of the different pasture systems was an outcome of the experiment. Each month, feed on offer (FOO) was determined and the number of stock in a paddock was adjusted if necessary to ensure that the average FOO on all systems was similar and aligned with achieving condition score targets set to optimise reproductive performance by following Lifetimewool guidelines.

Table 2. Matrix of pasture and sheep systems with potential lambing percentage (foetuses scanned per pregnant ewe) at experimental allocation for each year 2006 to 2009 (note all Merinos joined to terminal sires).

| Year | Novel pasture System | Ryegrass Pasture System | Triple Pasture System |

| 2006 & 2007 | Merino single lambs 100% | Merino single lambs 100% | Merino single lambs 100% |

| Merino twin Lambs 200% | Merino twin lambs 200% | ||

| 2008 | Merino scanned 129% | Merino scanned 129% | Merino scanned 129% |

| Coopworth scanned 179% | Coopworth scanned 179% | ||

| 2009 | Merino scanned *average 149% | Merino scanned *average 156% | Merino scanned *average 152% |

| Coopworth scanned average 185% | Coopworth scanned average 184% |

*In 2006, 2007 and 2008 each pasture system was allocated with sheep to ensure a set reproductive rate at lambing based on the scanning performance of all sheep. In 2009, the scanning rate was the “average” performance of the ewes that had been mated on the pasture system that had been allocated in 2008.

Coopworth composites (left) were compared to Merinos joined to terminal sires (right) and a heifer/steer backgrounding system (middle). Cows and calves were also run in 2009 and 2010.

Post-experimental modelling

Post-experiment modelling was conducted based on the results of the experiment to confirm findings at a farm scale and across more years than could be tested during the experiment. The modelling included the use of programs such as MIDAS, GrassGro, Gross margins analysis and whole farm case study analysis.

What was found?

Similar production from Merinos and Coopworths

Pre-experimental modelling showed that the most profitable sheep enterprise would be one that is able to produce both meat and wool in a dual-purpose enterprise with Merino ewes joined to terminal sires.

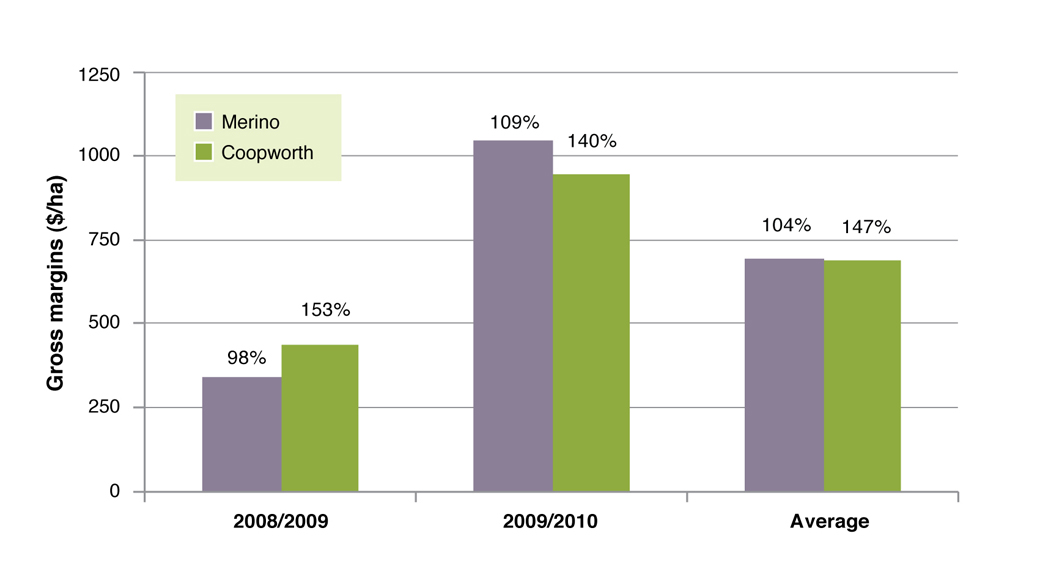

However, while modelling of the systems and benchmarking studies generally indicate this to be the case, gross margins from the Coopworth/Composite and Merino x Terminal enterprises at the Hamilton experiment were relatively similar in both years. The reason was that both systems performed well but differently in terms of reproduction and wool production.

Note, relevant lamb prices were sourced from the MLA National Livestock Reporting Service and wool prices were sourced from AWEX annual average market prices for each year.

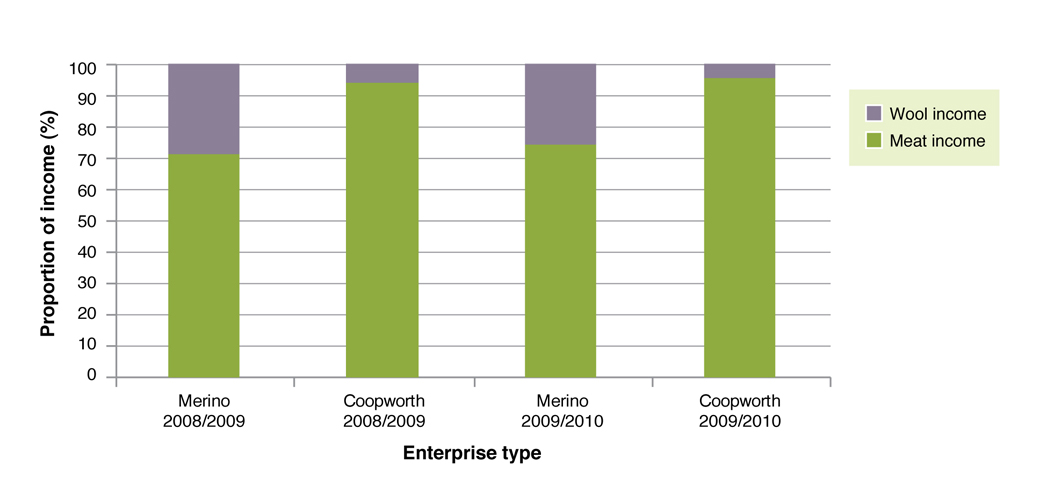

Nearly 30% of the income from the Merino x Terminal system was generated from wool compared to Coopworth/Composites that derived under 10% (Figure 2). This equated to nearly $400/ha extra in wool income for the Merino x Terminal system ($465 vs $85/ha).

This simply highlights the need for prime lamb systems that generate little wool income to have high reproductive rates generating more lamb income, if they are to be competitive with a Merino x Terminal operation (Figure 2, Warn et al. 2006). On average, the Coopworths marked 147% (lambs weaned per ewe lambed) compared to the Merinos marking 104% which equated to 70kg additional carcase weight per hectare due to more lambs that were slightly heavier, and this nearly made up the disparity in wool income. Note these weaning percentages do not account for dry ewes. The average lamb weaning percentages when accounting for dry ewes were approximately 92% for Merino ewes and 141% for Coopworth ewes. This compares to 80% and 118% for the average Livestock Farm Monitor Project.

For both sheep systems, the analysis assumed ewes were purchased in for replacements. The two major costs for the Coopworth system was the large ewe depreciation value and the supplementary feed costs. The supplementary feed costs were 76% higher for the Coopworths ($124) than for the Merino ($70/ha) reflecting the larger mature body size and that they had to be destocked earlier than the Merinos in some years and pasture systems. Whilst they were running at a similar DSE/ha they grazed pastures harder and reached minimum feed on offer and bare ground thresholds sooner than the Merinos.

Stocking rates lifted to potential

Using the relationship between growing season, current Olsen P levels and paddock size developed by Saul and Kearney (Table 3), a stocking rate target for the Hamilton region is around 20-23 DSE/ha. Note that topography, soil type and temperatures will also influence potential pasture growth and persistence, and therefore stocking rate, and are not accounted for in this data.

Table 3 Potential Stocking Rate (DSE/ha) for different length growing seasons, pasture fertility and paddock size. (Saul and Kearney 2002)

| Growing season (months) |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

Paddock size < 20ha |

||||||||

| Olsen P 10 |

11 |

14 |

17 |

20 |

24 |

28 |

31 |

34 |

| Olsen P 20 |

12 |

16 |

19 |

23 |

26 |

29 |

33 |

36 |

|

Paddock size > 20ha |

||||||||

| Olsen P 10 |

8 |

11 |

15 |

18 |

21 |

25 |

28 |

32 |

| Olsen P 20 |

10 |

13 |

16 |

20 |

23 |

27 |

30 |

33 |

A comparison with stocking rate data from western iLivestock Farm Monitor Project shows that on average most farms are running below this potential. District long term average over the last 41 years was 13.2 DSE/ha, and from 2007-2011 was 16 DSE/ha. The top 20% of producers (ranked according to gross margin/ha/100mm rain) were running around 20 DSE/ha during this period.

With the aim of significantly lifting profit, utilising new productive pasture species/cultivars that were well fertilised and rotationally grazed it was considered that utilisation rates and stocking rates could be lifted to around 30-32 DSE/ha. Over the 4 years (June 2006 – June 2010), the EverGraze project carried between 14 and 16 Merino ewes/ha (25 – 30DSE/ha) and 11-12 composite ewes/ha (27-31 DSE/ha).

More Merino ewes could be run because they had a lower standard reference weight (i.e. were smaller than the Coopworth/composite ewes and therefore had lower nutritional requirements). On an annualised DSE basis the Merino systems were averaging 28 DSE/ha, while the Coopworth system was averaging 31 DSE/ha and were also de-stocked from the pasture systems for longer during autumn in one year.

Higher variability in gross margins with increased stocking rates

The highest sustainable stocking rate for any particular sheep enterprise will balance production and environmental risks. There will be more risk associated with running the higher stocking rates and this will be reflected in income variability, increased supplementary feeding and increased probability that ground cover and feed on offer thresholds will be crossed.

GrassGro modelling for the EverGraze site (Warn 2011) demonstrated the increase in variability of gross margin when stocking rate increased on the perennial ryegrass system (Figure 3). Increased variation in the internal rate of rate of return and increased risk of variation in cash flow was also shown in modelling (Lewis et al. 2012) when improving 10% of a typical farm with EverGraze pasture systems and increasing stocking rate. However increasing stocking rate increased the average returns and reduced the payback period.

While the gross margin per hectare increases, the variability* of the gross margin became greater at higher stocking rates in excess of 18 Merino ewes/ha (34 DSE/ha, based on a 55kg ewe). The thresholds for feed on offer (< 800kg DM/ha by March) and supplementary feeding (>30 kg/ewe/year) were also exceeded more frequently up to 50% of the time at the highest stocking rate tested (Warn 2011).

* Variability is represented by the spread or the length of the “whisker/vertical line” on the box plot showing the range in gross margin per hectare. The tip at either end represents the maximum and minimum gross margins for all years evaluated.

Optimum lambing time

Modelling conducted by the Mackinnon project for the Sheep CRC evaluating many different sheep enterprises on regionally typical winter active pasture systems (Warn et al 2006), showed that to optimise gross margin, later lambing (spring) was suited to wool enterprises, and earlier lambing (winter-early spring) to lamb enterprises. The most profitable time of lambing was that with the greatest production for the lowest level of supplementary feeding. There was no economic benefit from lambing any earlier than June. To capture the benefits of later lambing stocking rate needed to be increased. Lambing prior to June constrained overall stocking rate and product/ha because maximum grazing pressure coincided with low winter pasture growth rates or if high stocking rates were to be maintained the ewes required increased supplementary feed to carry them through winter.

The guidelines for these different enterprises on regionally typical winter active pasture systems are illustrated in Figure 4 and described below.

- Lamb three months before the end of the growing season, if you run a self-replacing Merino operation carrying through Merino weaners or selling at 12 months of age for slaughter. A large proportion of income (over 70%) is still coming from the sale of wool so carrying more ewes results in greater wool cut/ha. The lambs/weaners can be carried through at lower growth rates and hence feed requirements (compared to lambs destined for slaughter) over summer/autumn.

- Lamb four months before the end of the growing season for flocks producing crossbred store lambs or light trade lambs, 44kg or 18 weeks of age (this assumes a 300g/day growth rate). If pasture quantity and quality cannot support these growth rates then lambing may need to start a month earlier to meet market specifications.

- Lamb five months before the end of the growing season for flocks producing crossbred lambs to be finished at heavier weights 53 kg or 26 weeks (may need to be finished on grain or lucerne).

The profitability of lambing later is a trade-off between the lower energy demands of the ewes at the autumn break and through the winter (because they are dry or in early pregnancy), versus the higher energy and protein requirements of the weaners that will be carried over into the summer/autumn. Later lambing makes it possible to carry higher numbers of ewes per hectare through the autumn and winter, and have more animals available to graze the spring flush. However, it also means that the lambs are smaller and younger when the pasture dries off, increasing the costs of feeding in summer, if they are carried through.

At Hamilton, EverGraze ran Merino and Coopworth ewes joined to terminal sires with the objective of turning off store lambs (35kg) before Christmas. The ewes lambed in September for the first three years of the experiment because that was modelled to be the most profitable using MIDAS (Young, 2004). This was moved to mid – August in 2009 because it was difficult to get the majority of the progeny to the store weight target in the drier years experienced, which had been characterised by below average rainfall in October. Lambing in mid – August meant that the ewes were lambing four months before the end of the growing season which matched the guidelines proposed by Warn et al. in Figure 4. A portion of the lambs were also able to be sold as finished lambs, while the remainder were sold as store lambs.

Changing the start time of lambing from 1st of August to 1st of July (sell lambs at 44 kg in mid-December) or 1st of September (sell lambs at 44 kg in mid-January) was modelled for the Merino x Terminal enterprise run on the Triple system at Hamilton (Warn 2011). This study showed that while lucerne in the Triple system extends the growing season in more years than the Perennial Ryegrass system it cannot do this in every year or over sufficient area (only 30% of the area is lucerne) to change the time of lambing and allow enough finishing feed for lambs. In only about 60 per cent of the years was the growing season able to extend into January and 30% into February, with sufficient levels of feed on offer to finish lambs. Therefore, like in the Perennial Ryegrass system, July lambing was most profitable when selling older finished lambs with higher sale weights – even though there were slightly less ewes run per hectare (reducing wool income). So, strategically, this study found it was less risky to follow the time of lambing guidelines proposed by Warn 2006 and then take advantage of extra turnoff weights in the wet summer seasons. Under these circumstances, gross margin per hectare could be increased through extra lamb weight and income per hectare.

For a store lamb producing system, summer active pastures may allow later lambing in September. Results from the Wagga Wagga Proof Site also provide insights into the most profitable lambing time for that environment with increased lucerne in the pasture system. This could also include use of split lambing to increase flexibility, enabling stocking rate to vary depending on the growing season.

Distribution of pasture growth and quality

Given pasture supply is chiefly constrained in autumn/winter when it most effects stocking rate and the number of ewes carried it would be expected that the value of extra pasture growth achieved during winter is more valuable than that achieved in spring. This is the case for all sheep enterprises (Table 4 from Young et al. 2004, Young et al. 2010).

This modelling (Young et al. 2004) also showed that pasture growth in early summer was of more value for meat focussed enterprises. In addition, maintaining pasture quality later into the season (modelled by reducing the rate of digestibility decline in a perennial ryegrass system, so that the final digestibility was 5% higher) increased profitability, particularly for meat focused enterprises.

Therefore increasing summer digestibility and pasture growth is more valuable for meat focussed systems than wool focussed systems, while winter pasture growth is critical for all sheep systems.

Table 4. Increase in profit ($/ha of pasture) achieved from varying pasture growth and herbage digestibility for 4 different flock/enterprise types (from Young et al. 2004).

| Wool focused enterprises | Meat focused enterprises | |||

| Traditional wool | Wool/meat | Wool-Meat to terminal | 1st cross | |

| 20% improvement in pasture growth rate for 1 week | ||||

|

2.70 | 2.40 | 2.60 | 2.50 |

|

1.60 | 1.60 | 2.00 | 2.45 |

|

0.60 | 1.20 | 2.10 | 3.15 |

|

0.10 | 0.45 | 0.70 | 0.45 |

|

0.10 | 0.10 | 0.25 | 0.01 |

| Reduced rate of digestibility decline in summer | 6 | 10 | 16 | 35 |

Benefits of higher reproductive rates vary with enterprise focus

The reproductive rate of sheep systems can be improved by increasing fertility (the number of ewes pregnant per ewe joined), prolificacy (the number of lambs born per ewe lambing) and survival (the number of lambs weaned per lamb born). The extra profit from increasing reproductive rate is a trade-off between the extra income achieved by having a flock with more surplus animals for sale and the extra costs associated with meeting the energy demands associated with more ewes pregnant or more ewes lactating.

A variety of methods can be used to increase reproductive rate. Flushing ewes on green pasture can achieve higher ovulation rates and ultimately scanning percentages (See Wagga Proof Site key message Flushing increases number of lambs born). Improving condition score at joining will also increase the scanning percentage, while improved condition during pregnancy and at lambing can increase lamb birth weight and lamb survival (See Lifetimewool). In these examples, summer active pastures through increased quality and quantity of feed could allow these increases in reproductive rate to be achieved.

Incorporating summer active perennials (such as in the Triple pasture system) is more valuable for meat focussed enterprises (Table 1. Young et al. 2004). Longer growing seasons mean that more lambs can be finished more cheaply and greater focus on meat increases the value of extra lambs.

In practice, EverGraze Hamilton used the separation of single and twin bearing ewes to illustrate the impact of high and low reproductive rate on the productivity and profitability of prime lamb production. Twin lambing systems produced more lambs per hectare and despite being at 5-7 kg lighter in liveweight at turnoff these systems produced 100-200 kg more lamb liveweight per hectare. Wool production (per head and per hectare) was also lower for twin lambing ewes but a lower fibre diameter improved price received. Consequently the gross margin from the twin lambing system was higher in both years across the pasture systems. These results highlight the potential for increased reproductive rates to increase farm productivity and profitability. However, the results could also have been even greater with higher lamb survival and it is important that any program to increase reproductive rate and weaning rate in an enterprise addresses the improvement of lamb survival as this is primarily where increased profit from reproduction arises (see Increasing lamb weaning percentage in South West Victoria; and EverGraze Exchange – Increasing the Survival of Lambs).

Putting the research into practice

A process for considering changes to livestock systems is discussed in detail in the EverGraze Exchange – Livestock systems for profitable use of perennials. The Wagga Wagga EverGraze Proof Site research page – Flexibility in livestock systems is important for risk management in variable climates, also provides data on the profitability of different sheep systems in the Wagga Wagga environment; focussing on time of lambing and the need to have sufficient flexibility to vary stocking rates to manage the seasons. Some of the key considerations are outlined below.

- Select an enterprise based on the skills, facilities, management expertise, interest and passion. Most economic benchmarking data of commercial farms suggests “it is not what you do but how well you do it”.

- Understand the length of the growing season, stocking rate potential based on soil fertility and climate.

- Determine the likely year in year out feed demand supply curves and establish thresholds for ground cover, feed on offer and supplementary feeding to manage risk.

- Critically evaluate the livestock system and the markets being targeted for lambs and wool and what is really required for profit/ha not just $/head.

- Optimise time of lambing to meet the market segment required and increase utilisation of pastures.

- Improve pastures to increase winter production and/or summer/autumn production

- Weaning percentages can be increased by following Lifetimewool guidelines and using shelter.

- Put in place management strategies to cope with animal health issues (e.g. worms, flies) and drought contingencies (such as facilities for destocking and containment feeding when required to preserve pastures and livestock).

If considering changes to stocking rate or lambing time, a good place to start is to calculate your current stocking rate profile. This can be done using the EverGraze stocking rate calculator. The average stocking rate can be compared to local benchmarks in the Livestock Farm Monitor Project, although these should be considered carefully as carrying capacity will vary based on the factors described above.

Once you understand your current stocking rate profile, you then need to work out your feed supply profile. The MLA Feed Demand Calculator provides growth curves for a range of different pasture species. The Hamilton Proof Site pasture growth curves are also a good reference for pasture growth that can be achieved for a range of pasture species. Using the Feed Demand Calculator, you can determine how well feed supply matches feed demand, and your current pasture utilisation. At higher rates of pasture utilisation, there will be higher risk of supplementary feeding costs in dry years and a greater demand for pasture and livestock monitoring and management skills. The availability of labour, facilities and capital also need to be considered when running higher stocking rates.

What it all means

Achieving profits from perennial pastures is at the most basic level about resource use efficiency. Pasture grown is usually the cheapest source energy and protein and the most profitable way to turn this into product is to improve utilisation, optimising the amount of clean wool or lamb product per hectare, while minimising feed costs.

Stocking rate is the biggest driver of pasture utilisation and profit; however this needs to be considered in the context of growing season, lambing date and enterprise type and their impact on production and variability.

Increasing stocking rate is key to capturing greater livestock production and profit from pasture improvements.

Lamb production systems are more profitable than a traditional self-replacing Merino enterprise, however the trade-off between high reproductive rates from a cross-bred ewe and high wool production from a Merino ewe mean there is little difference between these two options.

Producers must balance winter stocking rates with the trade off on lamb turn off weight for their pasture production profile. Lambing later will allow for higher stocking rates, but in a finished lamb production system, it is more profitable to lamb 4-5 months before the end of the growing season to enable lambs to be finished at higher weights.

Summer active perennial pastures, while not altering the most profitable time of lambing, can modify the herbage production profile and increase pasture growth during autumn, winter and summer, and this can significantly improve profit if the additional quality feed on offer is utilised. Capturing benefits from such pasture improvement is most likely when utilised by a lamb production enterprise achieving high reproductive rates.

Acknowledgements

EverGraze is a Future Farm Industries CRC research and delivery partnership. The Hamilton EverGraze Proof Site team was led by Dr Ralph Behrendt and consisted of scientists and technical staff from Agriculture Victoria. An enthusiastic Regional Advisory Group consisting of farmers, consultants, extension officers and Catchment Management Authority staff provided significant input into the direction, management practices and interpretation of outcomes from the experiment and modelling to make them relevant to farmers.

Further Information

- EverGraze Exchange – Making on-farm strategic decisions

- EverGraze Exchange – Livestock systems for profitable use of perennials

- Hamilton EverGraze research message – Right Plant Right Place Right Purpose Right Management

- Wagga Wagga EverGraze research message –Flexibility in livestock systems is important for risk management in variable climates

- Lewis C, Malcolm B, Farqueson R, Leury B, Behrendt R, Clark S (2012), Economic analysis of improved perennial pasture systems, Australian Farm Business Journal 9 (2), 37-56.

- Saul G, Chapman D (2002). Grazing methods, productivity and sustainability for sheep and beef pastures in temperate Australia.

- Warn, L. (2011) Hamilton EverGraze Proof Site: Report on the impact of changing management regimes on profitability. August 2011, Mackinnon, University of Melbourne

- Warn L, Webb Ware J, Salmon L, Donnelly J, Handcock D. Analysis of the profitability of sheep wool and meat enterprises in southern Australia – Final report for Project 1.2.6, February 2006.

- Young, J., Bathgate, A., Saul, G, Clark, S., Sanford, P., Friend, M. (2004). MIDAS Insights on profitably utilising perennial plants in Hamilton, Victoria. Report to the CRC for Plant Based Solutions to Dryland Salinity. 28 August 2004

- Young J.M., Thompson A.N. and Kennedy A.J. (2010). Bioeconomic modelling to identify the relative importance of a range of critical control points for prime lamb production systems in south-west Victoria. Animal Production Science. 50: 748-756

- Young, J. Bathgate, A. and Behrendt, R. (2011) Final MIDAS modelling for Hamilton EverGraze site.

- Saul GR and Kearney GA (2002) Potential carrying capacity of grazed pastures in southern Australia. Wool Technology and Sheep Breeding 50 492-98.